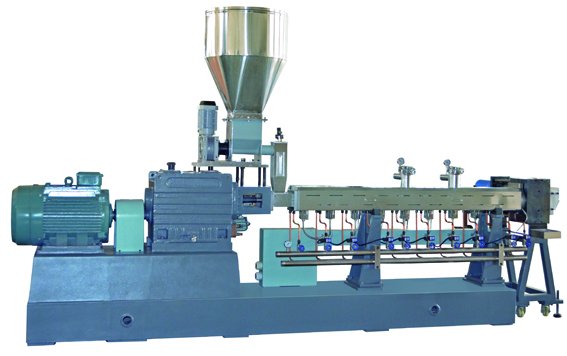

Plastic Twin Screw Extruder Graulating Machine

Basic Info

Model No.: TSSK65

Product Description

Model NO.: TSSK65

Plastic Processed: PP,PE,Pet etc.

Feeding Mode: Multiple Feed

Screw: Twin-Screw

Screw Channel Structure: Deep Screw

Automation: Automatic

Color: Green White and Blue

Screw Diameter: 62.4mm

Drive Motor Power: 55kw

Control Zone: 10

Trademark: PURUI

Specification: one 40 HQ

HS Code: 84778000

Type: Granulating Machine

Product Type: Granulating Extruder

Assembly Structure: Integral Type Extruder

Engagement System: Intermeshing

Exhaust: Exhaust

Computerized: Computerized

L/D: 40

Internal Diameter of Barrel: 63mm

Central Distance: 52mm

Lubrication: Oil Dipping

Transport Package: Packing

Origin: China

Twin Screw Extruder plastic granulating machine plastic machinery

1.Type:

High torque co-rotation twin screw extruder

2. Advantage:

a. Cylinder

Hard alloy steel sleeve

Watercourse optimized

With degassing exhauting design

Anti-returens

Side feeding

High efficiency

b. Screw element

Hard alloy steel

Screw thread curve optmized

Involute spline joint

Self-cleaning

Anti wearing

Double head and triple head available

C. Gear box

High torque desigh

Import international bearing

Lubrication full infusion lubrication

3.Application

It is widely applied in the filling, blend, modifying, strengthening of rubber-plastic and engineering resins, and the chloridizing of PP and Devolatilizing of the Superabsorbent resins. It can also be used in Masterbatch degradation, Polyurethane poly addition reaction extrusion; PET flake recycling etc.

Filling modifaction

Caco3

Talcum powder

BaSO4

TIO2

Ceramic powder

Wood flour /plant fiber

Other inorganic filler

Blending modification

Thermoplastic material/elastomer

Polymer alloys

Reinforce modification

Short glass fiber

Long glass fiber

Carbon fiber

Other whisker

Preparation of masterbatch

Carbon black masterbatch

Color masterbatch

Flame-retardant masterbatch

Degradation masterbatch

Other special functions masterbatch

Cable material

PVC cable material

Zero halogen cable material

PE TR-XLPE,DNH

PE cross-linking cable material

Special cable material

4. Model

Standard type

| Model | TSSK 20 | TSSK 30 | TSSK35 | TSSK50 | TSSK65 | TSSK72 | TSSK92 |

| Screw diameter(mm) | 21.7 | 30 | 35.6 | 50.5 | 62.4 | 71.2 | 91 |

| L/D | 32-40 | 28-48 | 32-48 | 32-48 | 32-48 | 32-48 | 32-40 |

| Rotary speed(RPM) | 600 | 400 | 400/600 | 400/500 | 400/500 | 400/500 | 400/500 |

| Main motor power(KW) | 4 | 11 | 11/15 | 37/45 | 55/75 | 90/110 | 220/250 |

| Capacity(Kg/h) | 2-10 | 5-30 | 10-80 | 20-150 | 100-300 | 300-600 | 600-1000 |

Reinfored type

| Model | TSSK 50B | TSSK 65B | TSSK75B | TSSK75D |

| Screw diameter(mm) | 50.5 | 30 | 35.6 | 50.5 |

| L/D | 28-48 | 28-48 | 28-48 | 28-48 |

| Rotary speed(RPM) | 500/600 | 500/600 | 500/600 | 500/600 |

| Main motor power(KW) | 55/75 | 90/110 | 132/60 | 200/250 |

| Capacity(Kg/h) | 120-280 | 180-400 | 250-650 | 500-1200 |

Contact us if you need more details on Plastic Recycling Machinery. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Granulating Machine、Plastic Machinery. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Twin Screw Extruder

Premium Related Products

Other Products

Hot Products

Stretch Film Recycling SystemPP/PE/PVC Waste Plastic Pulverizer MachineWaste Plastic Film Recycling and Pelletizing ExtruderWoven Bag/Jumbo Bag and Ton Bag Shredder MachineSingle Screw Pelletizing Granulating Extruder/ Plastic Recycling LineUsed Plastic Pipe Single Shaft ShredderUsed Pet Bottles Washing MachineMl75 PLC Control PP, PE Film Pelletizing Line Plastic Recycling MachinerySqueezing Dryer / Squeezing Machine for Plastic Film Screw DryerPlastic Shredder/Plastic Shredding Machine/Plastic GrinderPlastic Twin Screw Extruder Graulating MachinePlastic PE Film Squeeze DryerPlastic Film Crusher Crushing MachineCantilever Pelletizer Plastic Recycling MachinePlastic Recycling Line Plastic Pelletizing LineRecycled Plastic Granules Making Machine