Plastic Waste Recycling Machinery for PP PE Film Washing

Basic Info

Model No.: WSP600

Product Description

Model NO.: WSP600

Plastic Type: PP/PE/LDPE/HDPE/Pet/PVC/EPS/PS/ABS

Automation: Automation

Certification: SGS, ISO9001:2008, CE

Main Processes: Plastic Cutting, Washing and Drying

Capacity: 300kg/H to 1000kg/H

Auxiliary Equipment: Plastic Sorting System, Waste Water Treatment

Warranty Time: 13 Months

Installation: Engineers Availiable Oversea

Transport Package: Ship Request Package

Origin: China

Material Processed: Film

Screw: Single-Screw

Computerized: Computerized

Washing Material: PP PE Film, PP Woven Bag

Clean Waste: Sand, Stone, Oil, Milk, Hey and Other Sticky Thing

Machine Components: Crusher, Floating Tank, Squeezing Dryer

Delivery Time: 60 Days

Design Experience: 30 Years

Trademark: PURUI

Specification: QXL800

HS Code: 84778000

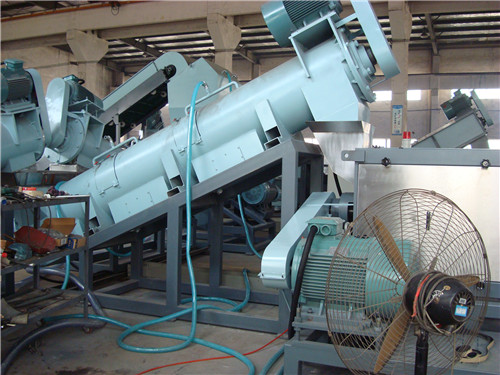

PP PE film washing line/plastic recycle washing machine/Plastic Recycling Machine

Product Description:

PURUI Recycling Machine (Crushing, Washing, Drying and Granulating)

PE/PP Film Recycle Washing Machines are special designed for post-agriculture film, post-commercial bag, post-industry film and post-consumer bag with sand, stone, powder, oil and other sticky waste.

Capacity range: 300kg/h to 1000kg/h

PURUI Recycling Machine Process Material :

Washing line can be used for PP woven bag, film and PE trash bag, film, packing material and some other loose material, agriculture film (1mm), industrial LDPE film with milk and powder, LDPE green- house film. Food packaging film, agriculture film, green house using film, film used in oil field, PP bag, PE film, woven bag, LDPE shrink film, nature film or heavy printed film, cement bag, oily bag, dirty bag

PURUI Recycling Machine Information:

Plastic film cutting, washing, recycling machine with high output and excellent clean ability

Whole plastic recycling line is used to crush, wash, dewater and dry the PP/PE film, PP woven bag

Simple structure, easy operation, large capacity, energy-saving, safety

Automatic controlling, compacted structure, excellent production ability, perfect clean ability

PP PE film shredding and crushing system (to crush the film into small scrap)

Plastic film friction washing system (to remove oil with firction force)

two main shafts rotating and sperating system (to remove sand, stone, milk powder)

plastic floating tank (film will spread into the tank

squeezing drying system ( to dry the film scrap within 5% water content)

Work process:

Belt conveyor-crusher-spiral, feeder-friction washer-spiral, feeder-floating tank-spiral, feeder (upload)-spiral, feeder (download)-hot washer-friction washer-spiral, feeder-floating tank-spiral, feeder-centrifugal dewatering-pipe dryer-silo

Main equipment

| Crushing | Double shafts film shredder To pre-crush the bail film/ film block into long scrap Plastic Granulator/crusher to further cut the long waste scrap into small scrap Wet crusher have 2 effects On one hand, to wash crushed scrap with water, on the other hand, water can protect cutters from high temperature. Crusher can be equipped with operating plate Easily operated with sharp cutters |

| Prewashing | Pre-washer This machine is mainly for cleaning PE/PP/PET plastic film and flakes that after crushing, to clean the dirty that mixed in the film. The inner two big shafts rotating in the rotating tank, material will be patting and washing with separating sticky waste. PURUI patent technology Film Prewashing Machine( two rotating shafts washer) Special feeding and washing blade design for big size film prewashing, the screen can remove most of dirty and 99% sand. It can protect the knives of the crusher to running longer time and more efficient. The waste film through the prewashing machine can reduce 80% dirty. The machine can be wet and dry washing. Trommel with roll drum fast rotating, the big waste will be filter by roll drum hole. The big waste will transfer out by bottom belt conveyor. |

| Washing | Floating tank Wash and separate the materials by material gravity and water gravity |

| Dewatering | Horizontal Centrifugal Dryer This machine is mainly used to dewatering the cleaning plastic film, centrifugal forces from high speed rotation for master shaft which throw plastic film and water against the screen, and water is drained from the screen. This machine is good effective on drying and high efficiency. |

| Squeezing & Aggregating | Squeezer and agglomerator inner structure: one huge screw embed in the squeezer. with screw rotating, material will be push and compress. at this time, the water go out from the filter. after that, with the heat from waste material friction, material will be heated into semi-melting. after that, through the die/mould, mterial will be compressed with high temperature. after that, material go through pelletizing system, and output the rigid scrap. This machine is less energy consumption and good drying performance, moisture content of the output material can be controlled between 5-10%. |

Equipment characteristic

| Capacity | 300-2000 kg/h |

| Application | food packaging film, agriculture film, green house using film used in oil field, PP bag, PE film, woven bag, LDPE shrink film or heavy printed film, cement bag, oily bag, dirty bag |

| Specification | Plastic Shredder/ Plastic Crusher, High Speed Friction Washer, Centrifugal Dewatering Washer, Spiral Feeder, Floating Tank, Spiral Feeder , Two Main Shafts Rotting Tank,Squeezer or Squeezer & Agglomerator. Easily operated with power saving |

| Output Type | crushing, washing, dewatering, drying,granulating and packaging The humidity of final output could be within 5%-10%. Material will be processed by crushing, washing, dewatering, squeezing & aggregating. The humidity of final output could be within 2%. |

| After-sales Service | Engineers avaliable aboard installation |

Company profile

PURUI GROUP

Chengdu PuRui Polymer Engineering Co. Ltd is one of the leading manufacturers of plastic recycling machines, Plastic Washing Line and related auxiliary equipment in China.

We are professional at the plastic pelletizing, plastic modification and plastic washing recycling system.

We have more than 30 years of experience in plastic extrusion pelletizing, plastic recycling and washing system.

Our plastic pelletizing system's unique advantages are screw design, high output, good degassing and good filter effect.

It is widely used for film recycling system, film granulation line, foamed material recycling pelletizing, and other waste plastic material recycling and pelletizing.

Our plastic washing line such as crusher with bearable resistance and sharp cutter, washing units, separating or sorting machine, drying system, and packaging system are of sound quality.

It has the PET bottle sorting cutting washing recycling line, plastic film cutting washing recycling line, home electrical cover washing line, car bumper and various bottles sorting/cutting/washing recycling line. All these lines have been widely used in 40 countries.

Our service

1. Pre-sale support

PURUI Recycling Machinery consists of 30 years-experience engineers.

13 years of making and exporting experience make sure PURUI made machine sound quality.

2. After-sale service

PURUI's skilled engineer are available to do aboard installation, commissioning & training on request.

3. Technical support

30 years experience of plastic recycling machine design

13 years experience of plastic recycling machine production

4. Advantages:

Professional design team with 30-year experiences

Washing line size can be design as customer need

Applying to various material

High efficiency and high performance

Save your labor and electrical cost

High processing capacity: 500-3500kg/hour

PLC integrated and separated control on each machine

Touchscreen panel, easy operation, monitor and maintenance

Machine raw material: high-quality 304 stainless steel, hard and bear resistance, make sure the long using life

Ensure no second pollution to flakes

Excellent clean ability

5. Additional information:

Floating, washing tank can be changed as per customer's needs

Machine component like shredder, crusher also add as per customer's needs

Washing line size can be prolonged and short as the process material dirty content like oil, sand, ink

Now, wiring dryer or screw dryer are available, dryer system is also according to the processing material thickness

In general, up 50 microns, wiring fried

Contact us if you need more details on Plastic Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Recycling Machine、Waste Plastic Processing Machinery. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Recycling Machine

Premium Related Products

Other Products

Hot Products

Stretch Film Recycling SystemPP/PE/PVC Waste Plastic Pulverizer MachineWaste Plastic Film Recycling and Pelletizing ExtruderWoven Bag/Jumbo Bag and Ton Bag Shredder MachineSingle Screw Pelletizing Granulating Extruder/ Plastic Recycling LineUsed Plastic Pipe Single Shaft ShredderUsed Pet Bottles Washing MachineMl75 PLC Control PP, PE Film Pelletizing Line Plastic Recycling MachinerySqueezing Dryer / Squeezing Machine for Plastic Film Screw DryerPlastic Shredder/Plastic Shredding Machine/Plastic GrinderPlastic Twin Screw Extruder Graulating MachinePlastic PE Film Squeeze DryerPlastic Film Crusher Crushing MachineCantilever Pelletizer Plastic Recycling MachinePlastic Recycling Line Plastic Pelletizing LineRecycled Plastic Granules Making Machine