Twin Screw Extruder Snacks Food Machine

Basic Info

Model No.: DR-65/70/85

Product Description

Puff Snacks Extruding Line

Instruction

Twin Screw Extruder Snacks Food Machine uses raw materials such as corn powder, rice powder, other additives, etc.

Twin Screw Extruder Snacks Food Machine can make all kinds of snacks with different shapes and sizes.

Twin Screw Extruder Snacks Food Machine takes corn flour, rice flour, corn grits, millet, etc as raw materials for production. "Low cost, high profits" is the suitable generalization of Snack food business line, especially for puff snack food production.

Twin Screw Extruder Snacks Food Machine was manufactured based on our abundant experience and international advanced technology. With the high quality, exquisite craft, good after sale service and steady performance, our machines were well sold in the world. Welcome to our website. If there is any question or requirement, please kindly send your inquiry to us. We will reply to you as soon as possible.

Flow

Mixer→ Screw conveyor → Twin screw extruder→ Air conveyor(Hoister)→ Electric dryer → Hoister → Oil Sprayer→ Flavoring roller(drum) → Cooling conveyor

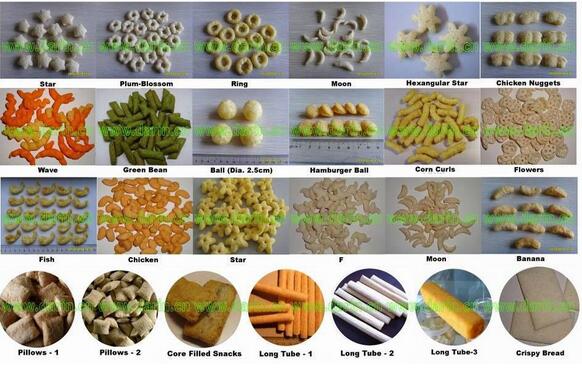

Various products can be produced by puff snacks extruding line

(1) Different shapes: Round ball, Circle ring, Bear, Star, Half moon, Curls, Flower, and Triangle, and so on.

(2) Method to change the shape: We will design the specific shape which you want to produce accordingly.

Technical Parameters

| Model | DR-65 | DR-70 | DR-85 |

| Capacity | 120-150kg/hr | 200-250kg/hr | 300-400kg/hr |

| Power | 95kw | 140kw | 160kw |

| Dimension | 18 x 5 x 3m | 20 x 5 x 3m | 22 x 5 x 3m |

Why Choose Us?

1. Motors are from WEG, Brazil, which has 3-year world-wide guarantee or Siemens;

2. Electric parts are from ABB or Schneider, easy to find replacments at local market;

3. PLC and touch screen are from Siemens, Germany to realize easier operation and less labor quantity;

4. PLC and touch scrren controls whole processing line, not one or two single equipment;

5. While faults occurred, relevant information will be displayed on touch screen, easy to settle the problem;

6. Control cabinet has 24V safe voltage (not 220V), which could protect the operator even electric leakage occurred;

7. Three kinds of protectors to keep machine and operator safe: over-current protector, over-voltage protector and over-heat protector;

8. All the cover body, mesh belt and parts touching with materials or final products are made by stainless steel 304.

Machine picture

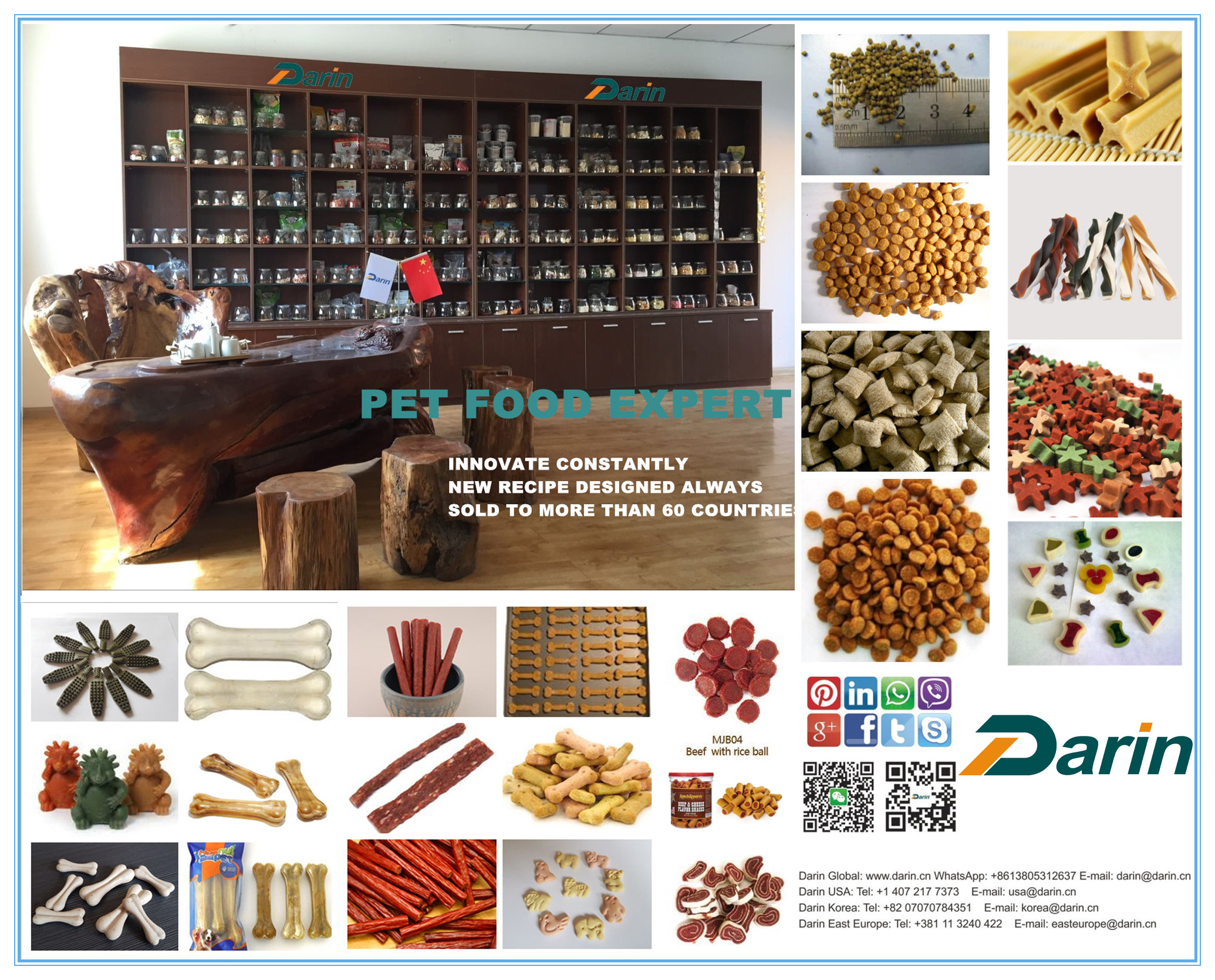

Clients from all over the world

Manufactured in DARIN

Key Equipment Show

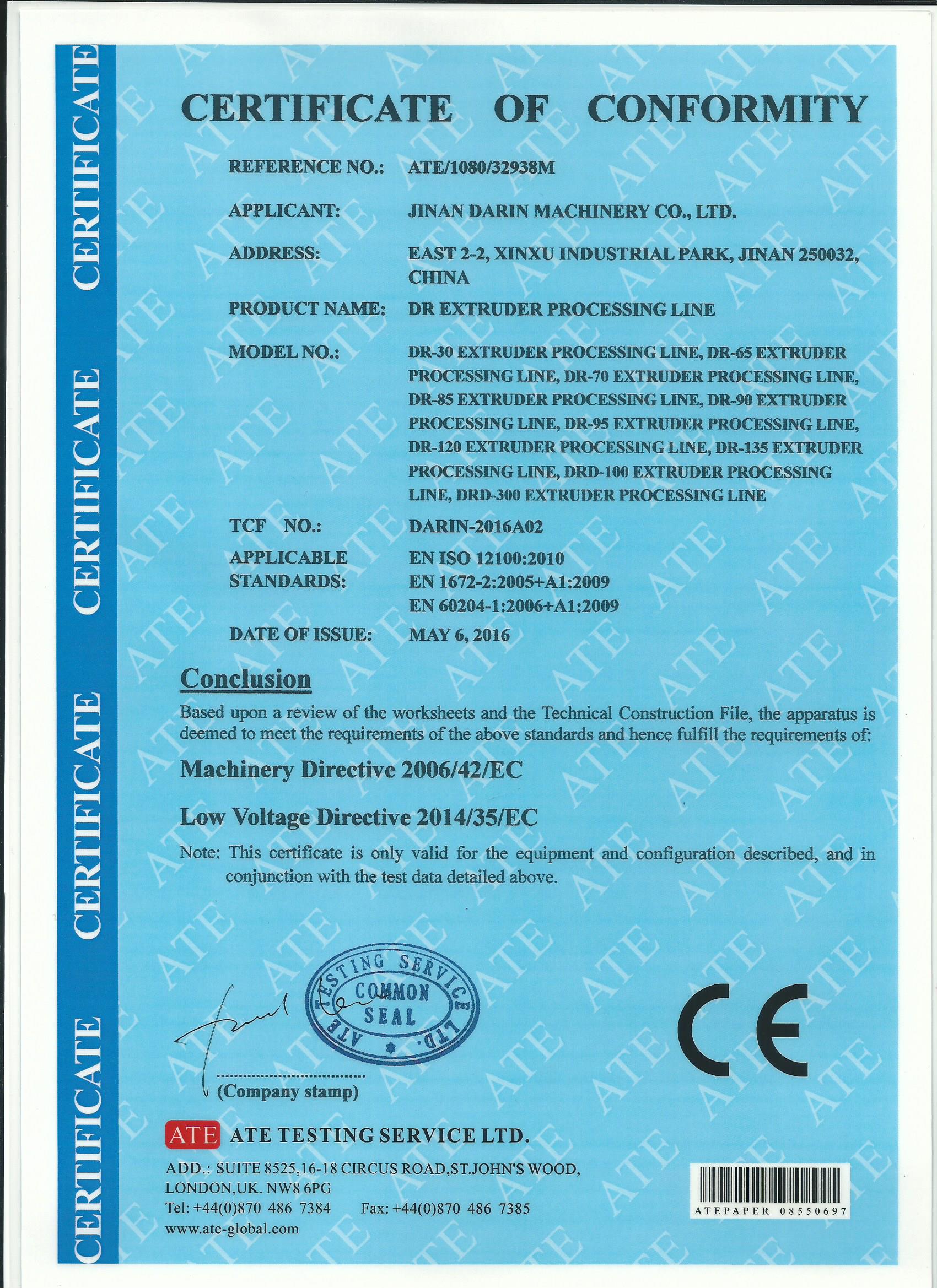

Certificate

Package & Shipping

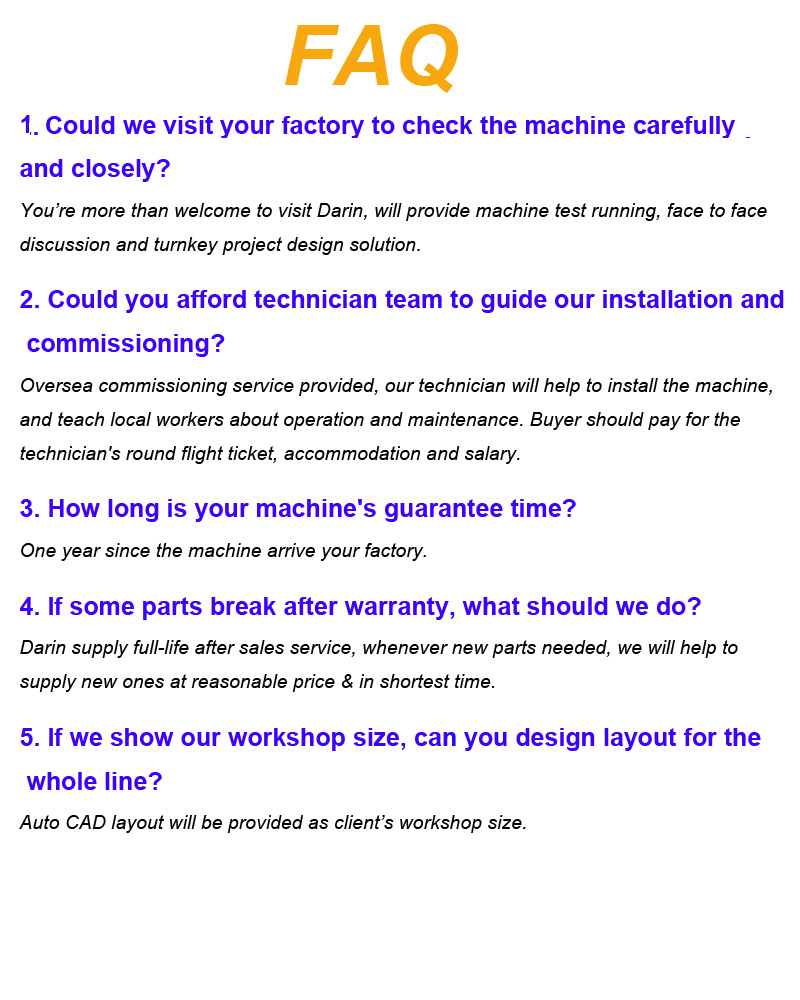

FAQ

Exhibition

Our factory

Contact

Product Categories : Food Extruder > Puff Snacks Extruding Line