Pet Plastic Bottle Washing Machine and Recycling Machine

Basic Info

Model No.: QXL6000

Product Description

Model NO.: QXL6000

Plastic Type: PET

Automation: Automation

Certification: SGS, ISO9001:2008, CE

Capacity: 300kg/H to 6500kg/H

Delivery Time: 60 Days

Machine Spare Parts: Offer Bearable Parts for Free

Design Ability: 30 Years Designing Experience

Machine Service Life: 10 Years

Transport Package: Ship Request Package

Origin: China

Material Processed: Plastic Bottle

Screw: Single-Screw

Computerized: Computerized

Application: Pet Bottle Sorting Crushing Washing Line

Machine Components: Sorting, Washing, Drying, Granulating

Warranty Time: 13 Months

Installation: Layout, Engineers Available Aboard

Machine Raw Material: 304 Stainless Steel

Trademark: PURUI

Specification: stainless steel

HS Code: 84778000

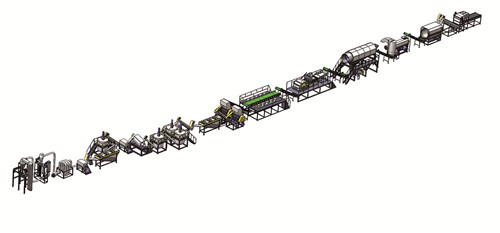

PET bottle washing line /PET bottle recycling plant/PET recycling process

PURUI Recycling Machine (Label Separating, Crushing, Washing, Drying and Granulating)

HDPE/PP/PET Bottle Recycle Washing Machines are special designed for PET bottle, HDPE milk bottle, PP /PE Bottle, HDPE blue jar, oil bottle, Jerry Can, Waste Plastic Container, Plastic Bucket, Plastic Hollow Bottle with sand, stone, powder, oil and other sticky waste.

Capacity range: 500kg/h to 6500kg/h

PURUI Recycling Machine Information

Plastic bottle label separating, cutting, washing, recycling machine with high output and excellent clean ability

Whole plastic recycling line is used to crush, wash, dewater and dry the PP/PE flake or rigid material

Simple structure, easy operation, large capacity, energy-saving, safety

Automatic controlling, compacted structure, excellent production ability, perfect clean ability

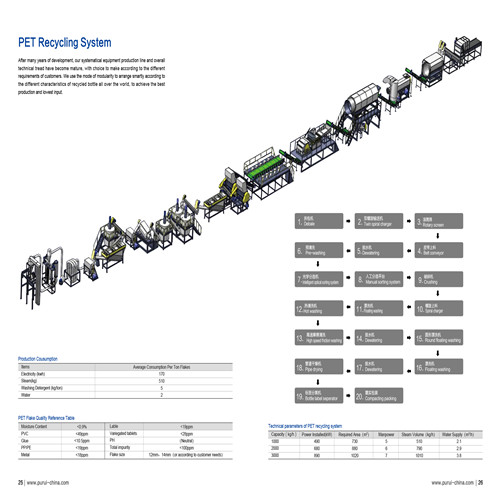

| No | Name | Function |

| 1 | Debale | To debale the |

| 2 | Twin spiral charger | Label sorting, intelligent sorting, manual sorting |

| 3 | Rotary screen | |

| 4 | Belt conveyor | |

| 5 | Dewatering | |

| 6 | Pre-washing | |

| 7 | Intelligent optical sorting system | |

| 8 | Manual sorting system | |

| 9 | Crushing | To crush the PET bottle into flake |

| 10 | Spiral feeder | Washing process |

| 11 | Floating tank | |

| 12 | Hot washer | |

| 13 | High speed friction washer | |

| 14 | Dewatering machine | |

| 15 | Round floating washing | |

| 16 | Floating tank | |

| 17 | dewatering | PET bottle flake drying process |

| 18 | Pipe drying | |

| 19 | Bottle label separator | To further remove the PE,PP label |

| 20 | Compacting packing |

final PET flake quality reference

| Moisture content | <0.9% | Label | <19ppm |

| PVC | <49ppm | Variegated tablets | <28ppm |

| glue | <10.5ppm | PH | (neutral) |

| PP/PE | <19ppm | Total impurity | <100ppm |

| Metal | <18ppm | Flake size | 12mm,14mm(customization) |

Equipment characteristic

| Capacity | 500-6500 kg/h |

| Application | PET bottle, HDPE milk bottle, PP /PE Bottle, HDPE blue jar, oil bottle, Jerry Can, Waste Plastic Container, Plastic Bucket, Plastic Hollow Bottle with sand, stone, powder, oil and other sticky waste. |

| Specification | Plastic Shredder/ Plastic Crusher, High Speed Friction Washer, Centrifugal Dewatering Washer, Spiral Feeder, Floating Tank, Spiral Feeder , Two Main Shafts Rotting Tank,Squeezer or Squeezer & Agglomerator. Easily operated with power saving |

| Output Type | crushing, washing, dewatering, drying,granulating and packaging The humidity of final output could be within 2%. Material will be processed by crushing, washing, dewatering |

| After-sales Service | Engineers avaliable aboard installation |

Our service

1. Pre-sale support

PURUI Recycling Machinery consists of 30 years-experience engineers.

13 years of making and exporting experience make sure PURUI made machine sound quality.

2. After-sale service

PURUI's skilled engineer are available to do aboard installation, commissioning & training on request.

3. Technical support

30 years experience of Plastic Recycling Machine design

13 years experience of plastic recycling machine production

4. Advantages:

Professional design team with 30-year experiences

Washing line size can be design as customer need

Applying to various material

High efficiency and high performance

Save your labor and electrical cost

High processing capacity: 500-3500kg/hour

PLC integrated and separated control on each machine

Touchscreen panel, easy operation, monitor and maintenance

Machine raw material: high-quality 304 stainless steel, hard and bear resistance, make sure the long using life

Ensure no second pollution to flakes

Excellent clean ability

5. Additional information:

Floating, washing tank can be changed as per customer's needs

Machine component like shredder, crusher also add as per customer's needs

Washing line size can be prolonged and short as the process material dirty content like oil, sand, ink

Now, wiring dryer or screw dryer are available, dryer system is also according to the processing material thickness

Iabel separating system to remove bottle label

Contact us if you need more details on Plastic Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Recycling Machine、Grinding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Recycling Machine

Premium Related Products

Other Products

Hot Products

Stretch Film Recycling SystemPP/PE/PVC Waste Plastic Pulverizer MachineWaste Plastic Film Recycling and Pelletizing ExtruderWoven Bag/Jumbo Bag and Ton Bag Shredder MachineSingle Screw Pelletizing Granulating Extruder/ Plastic Recycling LineUsed Plastic Pipe Single Shaft ShredderUsed Pet Bottles Washing MachineMl75 PLC Control PP, PE Film Pelletizing Line Plastic Recycling MachinerySqueezing Dryer / Squeezing Machine for Plastic Film Screw DryerPlastic Shredder/Plastic Shredding Machine/Plastic GrinderPlastic Twin Screw Extruder Graulating MachinePlastic PE Film Squeeze DryerPlastic Film Crusher Crushing MachineCantilever Pelletizer Plastic Recycling MachinePlastic Recycling Line Plastic Pelletizing LineRecycled Plastic Granules Making Machine