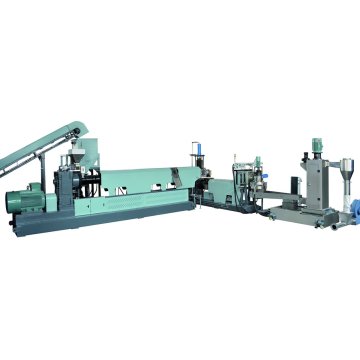

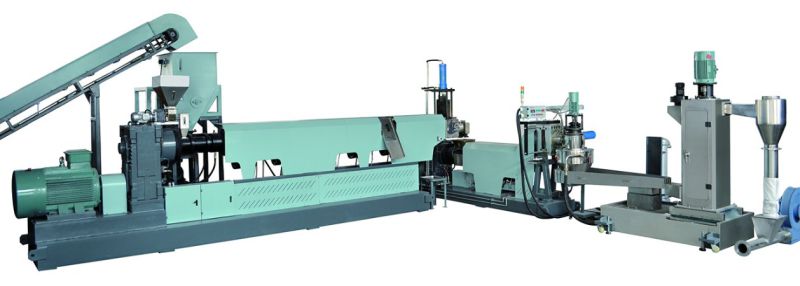

Washed PP PE Flake Granulating Machine for Recycling

Basic Info

Model No.: SJ140/SJ140

Product Description

Model NO.: SJ140/SJ140

Plastic Type: PP/PE/LDPE/LLDPE/HDPE

Automation: Automation

Certification: SGS, ISO9001:2008, CE

L/D: 33:1

Total Power: 132kw to 160kw

Delivery Time: 60 Days

Warranty Period: 13 Months

Screw Material: 38CrMoAl and Bimetalic

Transport Package: Ship Requested Package

Origin: China

Material Processed: Film

Screw: Single-Screw

Computerized: Computerized

Screw Diameter: 130mm

Capacity: 400kg/H to 650kg/H

Material Shapes: Film, Bag, Sheet, Net, Foam, Tapes

Application: Plastic Recycling, Waste Plastic Management

After Service: Engineer Avaliable Aboard

Trademark: PURUI

Specification: belt conveyor, main extruder, pelletizing system

HS Code: 84772010

PURUI washed plastic flake granulating extruder with side force feeder

project inroduction :

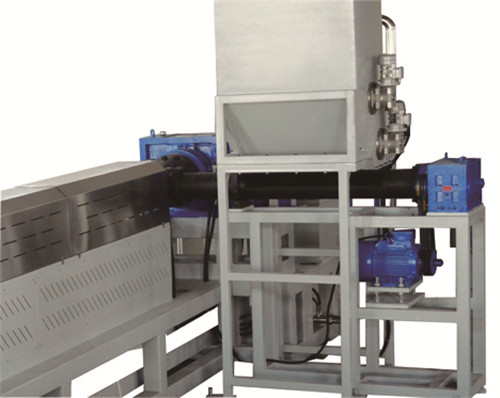

considering the film loose density, it is hard to feed to the main extruder.

as the wring dried or agglomerated film is in flake form, to adopt this kind extruder can save much cost.

machine smaple:

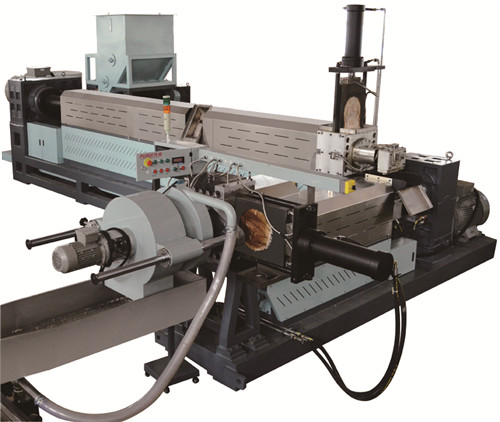

Quick details for plastic peleltizing Recycling Machine for recycling milk bottle, hollow bottle, board, or other rigid material

1. Rigid milk bottle, shampoo bottle, chemical barrel, pipes, rigid material, plastic product e.g.

2. Single stage, single screw

3. Pull strap pelletizing

4. CE certificate

5. Lower power consume,

6. More stable output

7. Smooth & full pellets

8. after sale service

Material shapes: agglomerated film, crushed material (PE, PP)

Description for Plastic Extruding machine for recycling rigid milk shampoo chemical flakes:

A. Features of film granulator:

Higher output, lower consumption, more automatic

20% more output than our first -generation products

15% less consumption than our first -generation products

2 labors operating the whole line

B. Applications of film granulator:

Applicable plastic materials: PE, HDPE, LDPE,PP, etc

Material shapes: rigid flakes, agglomerated film,

Note: depending on different material properties, various downstream equipments are needed.

C. How it works

1.Screw charger uploading the material by timer

2.Feeder and extruder is controller by inverter,

3.Different L/D for different material

4.Nature degassing, vacuum degassing adopting for moisture

5.Pull strap pelletizing for wide usings

Machine parameter

| Model | SJ30 | SJ45 | SJ65 | SJ90 | SJ100 | SJ120 | SJ150 | SJ160 | SJ180 | SJ200 |

| Screw diameter(mm) | 30 | 45 | 65 | 90 | 100 | 120 | 150 | 160 | 180 | 200 |

| L/D | 18 to 42 | |||||||||

| Rotary speed(rpm) | 10 to 150 | |||||||||

| Capacity(kg/h) | 2 to 40 | 10 to 60 | 100 to 150 | 180 to 250 | 250 to 350 | 300 to 600 | 400 to 750 | 800 to 1000 | 1500 to 2000 | 2000 to 3000 |

side force feeder with botom screw

(to solve the loose material's feeding problem)

machine details parts picture

final pellets sample

other related information for reference

| Model name | SJ |

| output | Plastic pellets/granules/resins/plastic raw material |

| Machine parts | Side force feeder, main extruder, hydraulic screen filter, second stage extruder, hydraulic screen filter,pelletizing unit, cooling system, silo, cabinet |

| Recycling material | washed PP/PE/LDPE/HDPE film, bag, fiber,flake |

| Capacity range | 100kg/h to 1200kg/h |

| Feeding way | Conveyor, roll driving system |

| Screw diameter | 75mm to 200mm |

| Screw L/D | 25 to 33 |

| Screw raw material | 38CrMoAl or bimetallic |

| degassing | Natural degassing, vacuum degassing |

| Cutting type | water ring pelletizing way, pull strip pelletizing |

| Cooling type | Water cool, air cool |

| voltage | Customized |

| Optional devices | Metal detector, water cooling system, feeding silo, vibration system |

| Delivery time | 40 to 60 days |

| Warranty time | 13 months |

| Technical supports | Machine layout, installation layout, engineer oversea service |

| certificate | CE/ SGS/ TUV/ CO |

Contact us if you need more details on Plastic Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Recycling Machine、Extruder. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Pelletizing Extruder

Premium Related Products

Other Products

Hot Products

Stretch Film Recycling SystemPP/PE/PVC Waste Plastic Pulverizer MachineWaste Plastic Film Recycling and Pelletizing ExtruderWoven Bag/Jumbo Bag and Ton Bag Shredder MachineSingle Screw Pelletizing Granulating Extruder/ Plastic Recycling LineUsed Plastic Pipe Single Shaft ShredderUsed Pet Bottles Washing MachineMl75 PLC Control PP, PE Film Pelletizing Line Plastic Recycling MachinerySqueezing Dryer / Squeezing Machine for Plastic Film Screw DryerPlastic Shredder/Plastic Shredding Machine/Plastic GrinderPlastic Twin Screw Extruder Graulating MachinePlastic PE Film Squeeze DryerPlastic Film Crusher Crushing MachineCantilever Pelletizer Plastic Recycling MachinePlastic Recycling Line Plastic Pelletizing LineRecycled Plastic Granules Making Machine