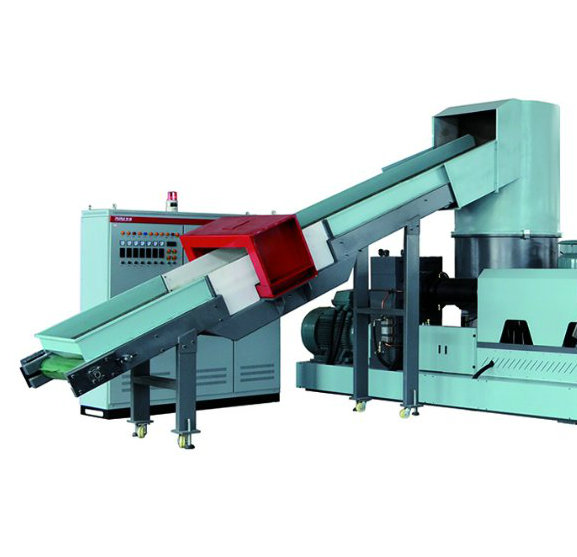

Plastic Recycling Line Plastic Pelletizing Line

Basic Info

Model No.: ML85

Product Description

Model NO.: ML85 Plastic Processed: LLDPE,PE,LDPE,HDPE,Pet Fiber,PLA etc Feeding Mode: One Feed Screw: Single-Screw Screw Channel Structure: Non Deep Screw Automation: Automatic Screw Diameter: 85mm Metal Detector: Yes Guarantee: 1 Year Training: Available Trademark: PURUI Specification: CE HS Code: 847720 Type: Granulation Extruder Product Type: Granulating Extruder Assembly Structure: Integral Type Extruder Engagement System: Non-Intermeshing Exhaust: Exhaust Computerized: Computerized Color: Blue Pelletizing: Watering Pelletizing Engineer to Install in Customer Factory: Available Capacity: 100-150kg/H Transport Package: Film and Plywood Packing Origin: China  Plastic recycling line plastic pelletizing line

Plastic recycling line plastic pelletizing line

Application

This plastic film pelletizing line can effectively process the waste plastic, such as post-industrial and post-customer PP, LDPE, PET, HDPE, PLA film and bags,PET fiber,EPE foam,etc.

If your film blowing factory has leftover bits and pieces, the machine will help you to recycle them and make pellets for film blowing.

If your factory recycle the post-customer PP,PE film and bags, you can recycle it with the machine and gets pellets for nest process.

Advantage

1. Easy to operate. Siemens PLC touch screen cotroller. One person to put material into the conveyor and one person to check the machine running.

2. Crushing, extruding and pelletizing intergrate skillfully. The cutter compactor crush, warm and compact the material to prepare the extrude.

3. Energy saving.

4.With metal detector to remove the metal.

5. Watering ring pelletizing to make pellets nice.

6. Cooling system is available as per customer requirement.

Model

Factory

Purui factory is professional in manufacturing the Plastic Recycling Machine, especially in the PP,PE granulation line and washing line. We have been exported plastic Recycling Machine to all over the world and got customers' acceptation. Any enquiry please contact us freely.

Packing and delivery

FIlm and plywood packing

Within 45 days after get your deposit, we will finish the machine. You can come to our factory to check and accept it. Then we will send the machine after get your balance amount of the machine.

After sale service

As per customer request, we could send engineer to install the machine in customer factory. Customer needs to pay the round tickets, visa application fee, lodging and boarding, 50USD per day for engineer.

Once any technical problem we will response at the first time to help you to solve it. Contact us if you need more details on PP PE Film Pelletizing Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Recycling Machine、Extruder. If these products fail to match your need, please contact us and we would like to provide relevant information.

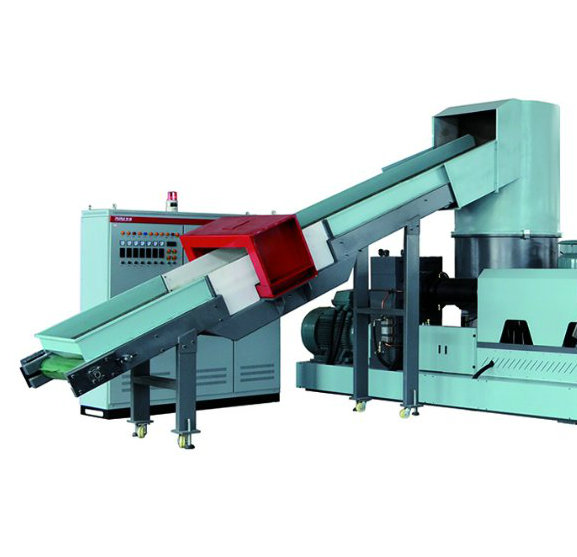

Plastic recycling line plastic pelletizing line

Plastic recycling line plastic pelletizing line

Application

This plastic film pelletizing line can effectively process the waste plastic, such as post-industrial and post-customer PP, LDPE, PET, HDPE, PLA film and bags,PET fiber,EPE foam,etc.

If your film blowing factory has leftover bits and pieces, the machine will help you to recycle them and make pellets for film blowing.

If your factory recycle the post-customer PP,PE film and bags, you can recycle it with the machine and gets pellets for nest process.

Advantage

1. Easy to operate. Siemens PLC touch screen cotroller. One person to put material into the conveyor and one person to check the machine running.

2. Crushing, extruding and pelletizing intergrate skillfully. The cutter compactor crush, warm and compact the material to prepare the extrude.

3. Energy saving.

4.With metal detector to remove the metal.

5. Watering ring pelletizing to make pellets nice.

6. Cooling system is available as per customer requirement.

Model

| Model | Output(kg/h) | Screw diameter(mm) |

| ML75 | 80-150 | 75 |

| ML85 | 120-180 | 85 |

| ML100 | 200-350 | 100 |

| ML130 | 400-550 | 130 |

| ML160 | 600-800 | 160 |

| ML180 | 800-1200 | 180 |

| ML200 | 1200-1500 | 200 |

Factory

Purui factory is professional in manufacturing the Plastic Recycling Machine, especially in the PP,PE granulation line and washing line. We have been exported plastic Recycling Machine to all over the world and got customers' acceptation. Any enquiry please contact us freely.

Packing and delivery

FIlm and plywood packing

Within 45 days after get your deposit, we will finish the machine. You can come to our factory to check and accept it. Then we will send the machine after get your balance amount of the machine.

After sale service

As per customer request, we could send engineer to install the machine in customer factory. Customer needs to pay the round tickets, visa application fee, lodging and boarding, 50USD per day for engineer.

Once any technical problem we will response at the first time to help you to solve it. Contact us if you need more details on PP PE Film Pelletizing Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Recycling Machine、Extruder. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Pelletizing Extruder

Premium Related Products

Other Products

Hot Products

Stretch Film Recycling SystemPP/PE/PVC Waste Plastic Pulverizer MachineWaste Plastic Film Recycling and Pelletizing ExtruderWoven Bag/Jumbo Bag and Ton Bag Shredder MachineSingle Screw Pelletizing Granulating Extruder/ Plastic Recycling LineUsed Plastic Pipe Single Shaft ShredderUsed Pet Bottles Washing MachineMl75 PLC Control PP, PE Film Pelletizing Line Plastic Recycling MachinerySqueezing Dryer / Squeezing Machine for Plastic Film Screw DryerPlastic Shredder/Plastic Shredding Machine/Plastic GrinderPlastic Twin Screw Extruder Graulating MachinePlastic PE Film Squeeze DryerPlastic Film Crusher Crushing MachineCantilever Pelletizer Plastic Recycling MachinePlastic Recycling Line Plastic Pelletizing LineRecycled Plastic Granules Making Machine