Basic Info

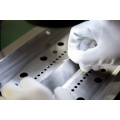

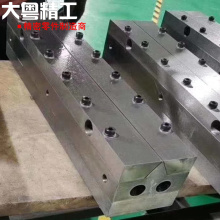

Model No.: 800mm

Click on the follow link to find out more information: https://www.idotechina.com/melt-blown-nonwovens-fabric-mould-1597447/

Company Info

- Company Name: Wuxi IDO Technology CO.,LTD

- Representative: xu yin

- Product/Service: Stamping die , Washing Machine Drum Assembly Equipment , Dishwasher Tub Assembly Line , stamping tool , metal stamping die , Washing Machine Production Line

- Capital (Million US $): RMB 10 million

- Year Established: 2014

- Total Annual Sales Volume (Million US $): Below US$1 Million

- Export Percentage: 1% - 10%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 4

- No. of R&D Staff: 31 -40 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: Building 4, Qingyun, Xishan science and technology entrepreneurship Park, No.99, Furong Middle Third Road, Xishan District, Wuxi City

- Contact Person: Mr. John.zhou

- Tel: 86-0510-83781892

Premium Related Products

Other Products

Hot Products

Stretch Film Recycling SystemPP/PE/PVC Waste Plastic Pulverizer MachineWaste Plastic Film Recycling and Pelletizing ExtruderWoven Bag/Jumbo Bag and Ton Bag Shredder MachineSingle Screw Pelletizing Granulating Extruder/ Plastic Recycling LineUsed Plastic Pipe Single Shaft ShredderUsed Pet Bottles Washing MachineMl75 PLC Control PP, PE Film Pelletizing Line Plastic Recycling MachinerySqueezing Dryer / Squeezing Machine for Plastic Film Screw DryerPlastic Shredder/Plastic Shredding Machine/Plastic GrinderPlastic Twin Screw Extruder Graulating MachinePlastic PE Film Squeeze DryerPlastic Film Crusher Crushing MachineCantilever Pelletizer Plastic Recycling MachinePlastic Recycling Line Plastic Pelletizing LineRecycled Plastic Granules Making Machine